Dry Ice Blasting – Clean with cold

Dry ice blasting uses the frigid temperature of dry ice “exploding” against the contaminant causing it to shrink and lose its adhesion. Dry ice is -109°F or -78°C.

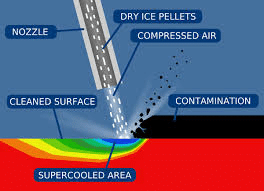

Dry blast cleaning uses small pieces of dry ice the size of rice to shoot them out of a jet nozzle with compressed air. The nozzle’s unique shape can cause the particles to accelerate faster than the speed of sound before hitting the surface to be cleaned. (see energies-12-04787 for analysis)

Some dry ice blasting machines shave a dry ice block for softer blast cleaning material.

Dry ice is softer than sand or glass beads, so it does not damage the underlying surface. It works like sandblasting, high-pressure water, or steam blasting with better results.

The combination of kinetic, thermal, and sublimation energy produces unparalleled results. The super cold temperature of the dry ice blasting against the material to be removed causes it to shrink and lose adhesion. Additionally, when some dry ice penetrates through the contaminated material and contacts the warmer underlying surface, it causes the dry ice to turn into a gas, expanding under the harmful material and speeding its removal.

Dry ice blasting does not create secondary waste or chemical residues and is

non-abrasive

non-conductive,

non-flammable,

and non-toxic.

It reduces personal contact with harmful chemicals and is an environmentally friendly cleaning method approved by the FDA, EPA, and USDA. Dry ice blasting can safely replace environmentally dangerous solvents and is less costly.

Before repainting old corroded flaking surfaces, dry ice blast cleaning is a better way to clean and prepare the surface for its new coating. The component is immediately available to paint – no waiting for drying or dangerous solvents to be removed.

Use a dry ice blaster to restore fire-damaged buildings and rooms – successfully removing the char and smoke damage to wood and other materials.

Many in-house uses for maintaining or cleaning equipment with dry ice blasters result in reduced downtime and higher annual production. The best solution may be an experienced professional contractor who can clean your equipment safely and quickly.

Start a new business or let your existing business meet more of your customer’s needs with dry ice blast cleaning. The latest blaster from Kärcher uses liquid CO₂ directly to make dry ice.

Before purchasing dry ice blast cleaning equipment that may cost anywhere from $15,000 to $50,000, consider renting. Also, some companies offer training for their equipment.

Find all this and more through the many professional companies presenting their equipment and services on this website.

Check out used dry ice blasting machines at DryiceClaaified.com

Include your dry ice blast cleaning services or equipment for new customer contacts.

Professional Companies Offering Services

RENT-LEASE-SALES

World’s Largest Rental Inventory

Stephen Telofski, Manager

732-447-5759

https://www.red-d-arc.com/blast-cleaning-equipment.aspx

At Enviro-Blast, we offer full-service dry ice blasting to many different industries.

586 756-4570

Warren, MI 48091

https://www.enviro-blast.com/

Sutton-Garten Co.

Sutton-Garten rents and sells used Cold Jet machines, nozzles, and blast hoses.

Please call us today for our inventory of equipment.

317-264-3236

https://www.suttongarten.com/

We are an eco-friendly industrial services company that specializes in cleaning and maintaining heavy industrial equipment and machinery.

https://www.emoryindustrial.com/

Dry Ice Works 800-451-8684

Serving Metro-Detroit, Southeastern Michigan, and Northern Ohio.

https://www.dryiceworks.com/

Authorized Distributor for

ICEsonic and Phoenix Unlimited LLC

https://www.dryiceblastingusa.com

Professional Companies Offering Services

Main Office

100 Cloniger Drive

Thomasville

North Carolina, 27360

Tel (336) 476-9274 Ex 2

E-Mail:

Web: dunnservice.com

CMC Dry Ice provides expert cleaning, restoration, and surface preparation throughout the Eastern United States as well as dry ice.

(980) 565-5224

www.cmcdryice.com

7160 Weddington Road NW, Suite 136

Concord, NC 28027

ACT Dry Ice Services

Practical innovative solutions

Harleysville

Pennsylvania 19438

215 913-4835

Web Address: actco2blasting.com

Email:

We serve the US (coast to coast)

We are a Texas-based industrial cleaning for the Gulf Region.

https://www.interstatecarbonic.com/

Service to Hydroelectric Power, Steam and Gas Turbine, Switchgear, and HRSG Units.

UNIVERSAL DRY ICE BLASTING – A Dry Ice Blasting Contractor Servicing the U.S.A. – Call or Email 760-525-8380 –

We proudly serve the aerospace, defense, automotive, food & beverage, energy, pharmaceutical, chemical, asphalt, concrete, and industrial cannabis and hemp for a wide variety of projects.

Los Angeles, CA

Jason Whipple

(619)559-6836

https://www.socalkryoblasting.com/

Professional Companies Offering Blasters