DryiceInfo

Choose to Sell Dry Ice?

SELLING DRY ICE

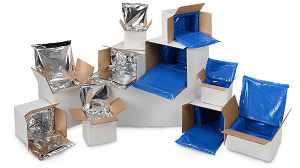

Selling dry ice is different from selling most other goods because the unsold amount disappears at 10% to 15% every day. Keep dry ice in a well-insulated storage container to reduce the loss rate. Dry ice sells by weight, so a good quality scale and suitable insulating gloves are necessary to handle it.

Very few people sell only dry ice. Do careful marketing research to establish the demand and determine the return on investment for manufacturing equipment. Distributing from a nearby manufacturer is often the best way to begin. Start-up costs are a minimum of $75,000 for making dry ice pellets and $120,000 for manufacturing solid block dry ice. An existing store, service station, or supply outfitter may add dry ice to help customers. Overall, grocery stores and markets choose to sell Airgas “Penguin” dry ice or dry ice from other manufacturers. Next are compressed gas suppliers and ice companies. Finally, some companies use dry ice to market or ship their products and offer to sell extra dry ice to the public.

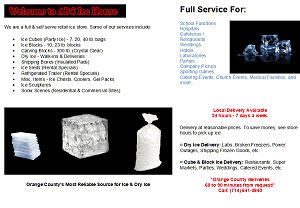

Our experience was with ABC Ice House for 24 years. They are a distributor selling about 100 tons a year. They have many walk-in customers for shipping frozen goods, and they supply shipping containers too. They also provide frozen gel packs for those who don’t want their food frozen but want to keep their product cool. Their customers use dry ice for camping and traveling, keeping items frozen. Ice cream vendors purchase dry ice to keep their ice cream frozen. Many fishers stop by for dry ice to keep their catch from spoiling. ABC Ice House often sells dry ice to power outages and broken refrigeration equipment customers. They deliver dry ice to many laboratories in the area, offering weekly or immediate delivery at a higher cost. Finally, they sell dry ice for theatrical special effects. They sell to a local “Mad Science” company that does parties and school assemblies. They also rent fog machines for unique theatrical productions, covering dance floors with fog and strobe lights.

Other dry ice customers include dry ice blasters, airlines, food shippers, medical institutions, bio-medical suppliers, pharmaceuticals, food processors, and manufacturers needing dry ice from time to time.

The key to selling dry ice is a constant supply by manufacturing it as needed or regular delivery from another manufacturer. It took over six months of selling dry ice before making a profit because the sublimation rate, in the beginning, was over 70%. Even now, it is close to 30% lost.